What Are the Benefits of Using RG Cable Series with Solid Polyethylene Dielectric?

Introduction to RG Cable Series

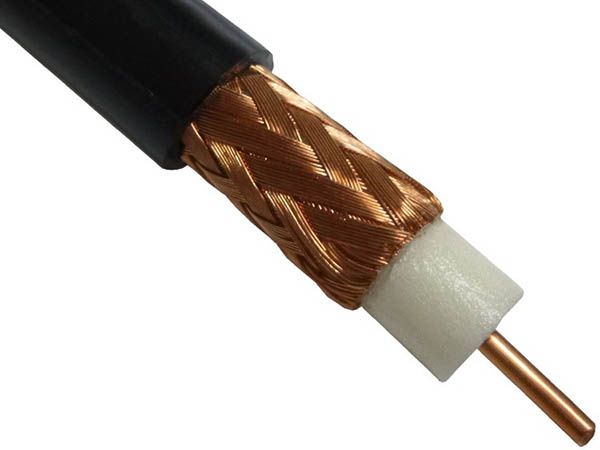

RG cable series, a staple in the world of coaxial cables, have been widely used for decades across various industries. These cables are known for their reliability and consistent performance, making them a preferred choice for many professionals. The "RG" stands for "Radio Guide," which dates back to World War II when these cables were standardized by the military for radio transmission applications. Over time, they have evolved to meet the demands of modern technology, ensuring efficient signal transmission in a wide range of applications.

The RG cable series encompasses several types, each designed for specific purposes. Some of the most common ones include RG-6, RG-59, RG-11, and RG-8. These cables differ in terms of impedance, dielectric materials, and overall performance characteristics. Among these, the RG cables with solid polyethylene dielectric stand out due to their unique properties and benefits. Understanding these advantages is crucial for anyone looking to optimize their communication systems, whether for residential, commercial, or industrial use.

Overview of Solid Polyethylene Dielectric

Solid polyethylene dielectric is a type of insulating material used in the construction of RG cables. Polyethylene is a thermoplastic polymer that offers excellent electrical insulation properties. When used as a solid dielectric in coaxial cables, it provides a stable and consistent environment for signal transmission. This material is chosen over others due to its low dielectric constant, meaning it can maintain signal integrity without significant loss or distortion.

One of the key features of solid polyethylene dielectric is its homogeneity. Unlike foam or air-dielectric cables, where the dielectric material may contain voids or inconsistencies, solid polyethylene provides a uniform medium throughout the cable. This uniformity ensures that the electromagnetic fields within the cable are well-contained and do not suffer from variations that could lead to signal degradation. Additionally, solid polyethylene dielectric offers better mechanical stability, protecting the cable's internal structure from physical stress and environmental factors.

Key Benefits

Enhanced Signal Integrity

One of the primary benefits of using RG cable series with solid polyethylene dielectric is the enhanced signal integrity. Signal integrity refers to the quality and consistency of the signal as it travels through the cable. With solid polyethylene dielectric, the signal experiences minimal loss and distortion, ensuring that the received signal is as close as possible to the transmitted one.

This is particularly important in applications where high-quality signal transmission is critical, such as in digital television (TV), internet broadband, and data communication systems. In these scenarios, any signal degradation can result in poor picture quality, slow data speeds, or even complete loss of connectivity. By using RG cables with solid polyethylene dielectric, users can be confident that their signals will remain intact and reliable throughout the transmission process.

Improved Durability

Another significant advantage of RG cable series with solid polyethylene dielectric is their improved durability. These cables are designed to withstand harsh environmental conditions, making them suitable for both indoor and outdoor installations. The solid polyethylene dielectric provides excellent resistance to moisture, temperature fluctuations, and physical damage.

For example, in outdoor applications where the cables are exposed to rain, snow, and extreme temperatures, the solid polyethylene dielectric ensures that the cable's performance remains unaffected. Similarly, in industrial settings where cables may be subjected to mechanical stress or chemical exposure, these cables can maintain their structural integrity and continue to function effectively. This durability translates into longer cable life and reduced maintenance costs, providing long-term value for users.

Lower Loss and Attenuation

Lower loss and attenuation are crucial factors in determining the efficiency of a coaxial cable. Loss refers to the reduction in signal strength as it travels through the cable, while attenuation is the rate at which this loss occurs. RG cable series with solid polyethylene dielectric offer lower loss and attenuation compared to other types of cables, making them ideal for long-distance signal transmission.

The low dielectric constant of solid polyethylene dielectric plays a significant role in achieving lower loss and attenuation. It allows the signal to propagate more efficiently through the cable, reducing the amount of energy lost as heat or radiation. This means that even over extended distances, the signal remains strong and clear, ensuring reliable communication between transmitting and receiving devices. Additionally, the solid nature of the dielectric material helps to minimize signal reflections and impedance mismatches, further reducing loss and attenuation.

Applications of RG Cable Series with Solid Polyethylene Dielectric

Coaxial Cabling

Coaxial cabling is one of the most common applications of RG cable series with solid polyethylene dielectric. Coaxial cables consist of an inner conductor surrounded by a dielectric insulator, an outer conductor (usually a braided shield), and an outer jacket. These cables are widely used for TV distribution, cable internet, and satellite communications.

In TV distribution systems, RG-6 cables with solid polyethylene dielectric are commonly used to connect satellite dishes, antennas, and set-top boxes to televisions. These cables provide high-quality signal transmission, ensuring clear and crisp images on the screen. For cable internet applications, RG-6 cables can support high-speed data transfer rates, allowing users to stream videos, download files, and browse the web without experiencing buffering or lag.

Antenna Feeds

Antenna feeds are another important application of RG cable series with solid polyethylene dielectric. Antennas require a reliable connection to transmit and receive signals effectively. RG cables with solid polyethylene dielectric are often used as feed lines to connect antennas to receivers or transmitters.

In broadcasting applications, such as AM/FM radio and television broadcasting, these cables ensure that the signals from the antenna are transmitted to the studio or transmitter with minimal loss. This is essential for maintaining the quality of the broadcast signal and ensuring that listeners or viewers receive clear reception. Similarly, in amateur radio and two-way radio communications, RG cables with solid polyethylene dielectric can be used to connect handheld transceivers to external antennas, extending their range and improving signal clarity.

RF Signal Transmission

RF (radio frequency) signal transmission is a broad field that includes various applications such as wireless communications, remote sensing, and radar systems. RG cable series with solid polyethylene dielectric play a vital role in these applications by providing a reliable means of transmitting RF signals over short or long distances.

In wireless communication systems, such as cellular networks and Wi-Fi networks, RF signals need to be transmitted from base stations or access points to mobile devices or clients. RG cables with solid polyethylene dielectric can be used to connect different components within these systems, such as antennas, amplifiers, and filters, ensuring efficient signal flow and minimizing signal loss. In remote sensing applications, such as weather monitoring or satellite imaging, these cables can be used to transmit data from sensors to processing units, enabling real-time analysis and decision-making.

Comparison with Other Dielectric Materials

When comparing RG cable series with solid polyethylene dielectric to those with other dielectric materials, such as foam or air, several differences emerge. Foam dielectric cables, for example, have a lower dielectric constant than solid polyethylene dielectric cables. This can result in slightly higher signal speeds but also makes them more susceptible to moisture absorption and physical damage. Air-dielectric cables, on the other hand, offer the lowest dielectric constant but are more expensive and difficult to manufacture.

Solid polyethylene dielectric cables strike a balance between these extremes. They provide good signal integrity, reasonable cost, and excellent durability. While they may not offer the same level of signal speed as foam dielectric cables or the same level of performance as air-dielectric cables, they are generally more versatile and practical for a wide range of applications. Additionally, their solid construction makes them easier to handle and install, reducing the risk of damage during deployment.

Installation and Maintenance Tips

Proper installation and maintenance are essential for maximizing the benefits of RG cable series with solid polyethylene dielectric. Here are some tips to ensure optimal performance:

Installation Tips

- Choose the Right Cable: Select the appropriate RG cable type based on your application requirements. Consider factors such as impedance, frequency range, and environmental conditions.

- Use Quality Connectors: Ensure that you use high-quality connectors compatible with your cable type. Poor-quality connectors can introduce signal loss and degrade performance.

- Minimize Bends and Twists: Avoid sharp bends and twists in the cable during installation. This can cause signal reflections and impedance mismatches, leading to signal loss.

- Secure the Cable: Use clips or straps to secure the cable along its path. This will prevent it from moving or vibrating, which could affect signal quality.

- Follow Manufacturer Guidelines: Adhere to the manufacturer's guidelines for installation, including minimum bend radius and maximum cable length.

Maintenance Tips

- Regular Inspections: Periodically inspect the cable for signs of wear, damage, or corrosion. Pay attention to connectors and terminations, as these are common failure points.

- Clean the Cable: If the cable is exposed to dusty or dirty environments, clean it regularly to remove any contaminants that could affect performance.

- Check for Moisture: Ensure that the cable is not exposed to excessive moisture. If necessary, use waterproof connectors or sealants to protect the cable ends.

- Monitor Performance: Use test equipment to monitor the cable's performance over time. Look for any changes in signal strength or quality that could indicate a problem.

- Replace Faulty Cables: If you detect any issues with the cable, replace it promptly to avoid prolonged downtime and ensure continued reliable operation.

Conclusion

In conclusion, RG cable series with solid polyethylene dielectric offer a range of benefits that make them an excellent choice for various communication applications. From enhanced signal integrity and improved durability to lower loss and attenuation, these cables provide reliable and efficient signal transmission. Their versatility extends to coaxial cabling, antenna feeds, and RF signal transmission, making them suitable for a wide range of uses. When compared to other dielectric materials, solid polyethylene dielectric strikes a balance between performance and practicality. Proper installation and maintenance are essential to maximize the lifespan and performance of these cables. Whether you are setting up a home entertainment system or a complex communication network, RG cable series with solid polyethylene dielectric are a dependable solution worth considering.

FAQ

What is the main difference between solid polyethylene dielectric and foam dielectric in RG cables?

The main difference lies in their dielectric constants and physical properties. Solid polyethylene dielectric has a higher dielectric constant compared to foam dielectric, which results in slightly lower signal speeds but offers better moisture resistance and durability. Foam dielectric cables are more susceptible to moisture absorption and physical damage but can provide slightly faster signal transmission due to their lower dielectric constant.

Can RG cables with solid polyethylene dielectric be used outdoors?

Yes, RG cables with solid polyethylene dielectric are suitable for outdoor use. They are designed to withstand harsh environmental conditions such as rain, snow, and extreme temperatures. Their solid construction provides excellent resistance to moisture and physical damage, ensuring reliable performance even in outdoor installations.

How do I choose the right RG cable for my application?

To choose the right RG cable for your application, consider factors such as impedance, frequency range, and environmental conditions. For example, if you need a cable for high-frequency applications like satellite communications, you may opt for RG-6 cable with solid polyethylene dielectric. If your application requires greater flexibility and lower weight, you might consider RG-11 or RG-59 cables. Always refer to the manufacturer's specifications and consult with a professional if needed.

Mobile Signal Booster

Mobile Signal Booster